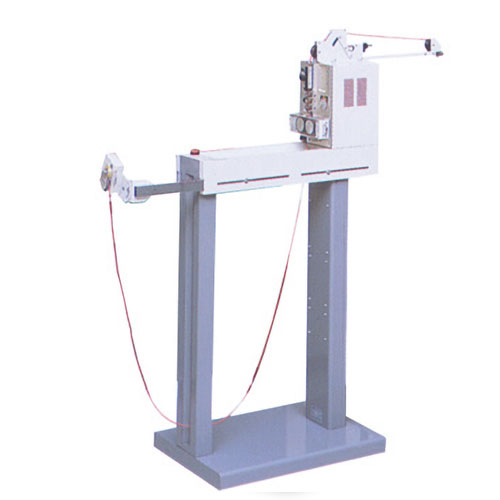

Cosmic 42R

เครื่องปอกสายไฟแบบใบมีดหมุน ปอกหลายชั้น สำหรับสายโคเฮ็คเซียลและสายมัลติคอร์

Cosmic 42R – Coaxial Wire Stripper

CABLE AND WIRE STRIPPER

- Area of application

- The Cosmic 42R stripping machine is used for micro-coaxial cables involving especially tough precision requirements. Cosmic 42R optimally processes coaxial cables, triaxial cables and cables with especially thin, hard or tough insulation.

- Conductors with braided insulation, e.g. polyester fibers, also belong to the processing range.

- The Cosmic 42R is ideal for a great diversity of products made in small to medium quantities.

- Rotating stripping head with centring

- The blade head of the Cosmic 42R is fitted with three blades and three centring units. Stripping with rotating blades and centring offers major advantages:

- - The centring unit positions the cable with precision.

- - The rotating blades cut the entire circumference of the insulation with precision.

- - The force needed for pull-off is reduced to a minimum.

- Multi-step stripping

- The Cosmic 42R strips multi-layered conductors in up to 9 steps. The processing steps can be programmed in any desired order. The cutting

- parameters can be independently set and optimised for every level. The Cosmic 42R has a memory that accommodates 1000 different conductors along with all processing parameters.

- Micro-coaxial connectors put the toughest demands on the precise processing of multilayered conductors. The Cosmic 42R carries out all cuts with ultra-precision and creates the best prerequisites for a top quality coaxial connection.

- Twisting conductor tips

- Twisting the tips of conductors prevents splayed stranded wires. The twisting function of the Cosmic 42R prepares the cable in an optimum way for being handled during assembly or tinning.

- Operation

- The operation of the Cosmic 42R is intuitive. The graphical display assists the operator with setting the processing parameters. Parameters such as the turning and feed speed, cut duration, pull-off speed etc. are presented in an straight-forward table.

- Features

- - Highly precise processing of micro conductors

- - Stripping in up to 9 steps

- - Ease of operation

- - Extremely low maintenance

- - Light and portable

| Outside diameter of the conductor (coaxial) | Approx. 0.5 mm – 2 mm | 0.012 in. – 0.08 in. |

| Conductor cross section(discrete conductor) | 0.005 mm² – 1.5 mm² | AWG44 – 16 |

| Minimum diameter of inner conductors | 0.05 mm | 0.002 in. |

| Resolution diameter | 0.01 mm | 0.0004 in. |

| Maximum pull-off length | 40 mm | 1.6 in. |

| Increment of pull-off length | 0.01mm | 0.0004 in. |

| Maximum stripping steps | 9 | |

| Cycle time | 6 seconds | |

| Production rate | Approx. 600 pcs/h (depending on conductor and programming) | |

| Database capacity | 1000 programs | |

| Gripper force | Adjustable in 10 increments | |

| Electrical connection | 1 × 100 – 240 V | 50/60 Hz | 120 VA | |

| Pneumatic connection | 5 – 7 bar | 73 – 102 psi |

| Noise emitted | Type < 50 dB (A) | |

| Dimensions (W × H × D) | 140 × 243 × 570 mm | 5.5 × 9.6 × 22.4 in. |

| Weight | 9.2 kg | 20.3 lbs |

| CE conformity | Complies with the EC directives on machine safety and electromagnetic compatibility | |

| RoHS | Complies with the Restriction of Hazardous Substances Directive (RoHS) |

In case of doubt, we recommend that you have samples made of the conductors before making a purchase.

| Full stripping | |

| Half stripping | |

| Multi-step stripping | |

| Coaxial and triaxial cable processing | |

| Coaxial and triaxial cable processing |